|

|

Ultrasonic Atomizers

|

(No Longer Available)

|

|

|

How it Works |

|

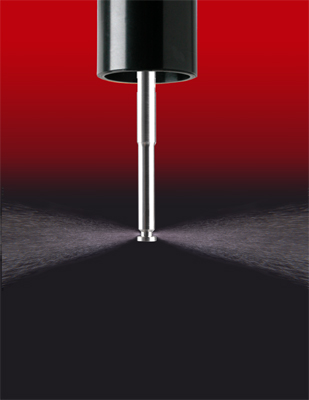

The ultrasonic atomizer nozzles are a flow through design. Liquid is pumped at the rear of the probe and travels down through the center until it reaches the vibrating tip. Once the liquid reaches the tip portion of the nozzle, ultrasonic vibrations pulverize the liquid into ultra fine particles for precise coating applications without the use of air pressure.

In the center of the probe are piezo ceramics which convert the electrical signal to mechanical vibration. This vibration is amplified by the step that forms the tip of the probe, and is reflected back towards the piezo ceramics , mixes with outgoing waves, creating standing waves. These standing waves cause a pumping action that sucks liquid towards the center of the probe.

With the Ultrasonic Atomizer probe design, liquid will spray continuously, will not flow back into the probe from these standing waves, creating a sudden spurt of liquid, called "flashing". The spray from these atomizers will be smooth and controllable with very little over spray. Spray thickness is nano - microns which is all user adjustable. The thickness is set by the pumps flow rate or shot, power level of the nozzle, liquid characteristics and the time the substrate is exposed to the liquid. For heavy coatings use low frequency probes, for ultra thin coatings use the higher frequency probe nozzles listed below.

We can have 304 or 316 stainless steel nozzles and components custom made for customers who require these materials as a special order. Any frequency nozzle ( 20kHz - 60kHz) can be designed and made from these materials. Flow rates maybe different from the list below. Seals can be either Viton or PTFE Teflon. Probe case, tube and back cover can be made in stainless steel. See DWG below for standard materials.

Description:

Ultrasonic atomizers come standard with flow through design for introducing liquids from the back of the probe. The atomizer transducer is made from titanium & stainless steel and has TEFLON O-rings for atomizing many different types of solutions. Ultrasonic atomizers are easy to clean, maintain, do not clog and have no moving parts to wear out.

Without the use of air pressure, low viscosity liquids are pumped through the center of the probe, where it is atomized into fine particles. The particles are then used in processes either for coating, burning, moisturizing, making nano particles or other applications that require particles made from liquids. The ultrasonic atomizer designs are anti-flashing, preventing liquid from reversing back into the probe from ultrasonic standing wave vibration and bursting out from the tip causing irregular droplets to be formed. Smaller and more uniform droplet size is a benefit from this type of liquid atomization.

Atomizers come with Atomizer Digital Ultrasonic Generator, which includes variable power control, timer functions and external enable/disable interface.

Syringe Pumps are recommended pumps for smooth liquid flow.

Features:

- Flow Through Probe Design

- Smaller orifice sizes for very low flow rates, down to .020"

- Smooth operation, anti-flashing design

- Titanium and stainless steel Construction

- Pressure fitting for easy attachment of fluid lines

- Welded Stainless Steel construction

- SMA connector at rear for easy attachment of transducer cable

- Different Spray Patterns Available

- Extended Lengths Avaiable

- Various Tip Configurations

- Flanges also available, special order

- Uses Atomizer Digital Ultrasonic Generator

|

Particle Size:

The average atomized or nebulized particle size is related to the surface tension (T), density (p) and the frequency (f) of the liquid. The following Lang formula will help in determining particle size.

In the case of water, where T=.0729N/m, p=1000kg/cu. m and f=50kHz, the size of the particles centers around 22.5 microns |

|

|

|

Wide Spray Ultrasonic Atomizers come with both ultrasonic generator and nozzle included. Purchase of parts separately is available as well.

|

Description:

- These ultrasonic atomizer nozzles have the widest spray pattern due to the tip design. 20kHz-60kHz nozzle have an upside down umbrella shape tip whereas the 120kHz and 130kHz nozzle has a convex tip shape. Sprays in the ul range will be similar to the Narrow series below and will get wider as the flow rate increases. Drop diameter provided is with the Lang formula below. For actual measured particle data using a DCIII particle counter see DATA link next to each nozzle.

- The tube connection at the rear is for a 1/8" diameter Swage-lock, allowing connection of various fittings and manifolds for introduction of multiple liquids and gases.

|

|

Model |

Item

description |

Flow Rate |

Drop Diameter (microns) |

Particle Distribution Data |

Photo |

Drawings |

Weight

(grams) |

| UAG-20K-W |

20kHz

Wide Spray Ultrasonic Atomizer |

0 - 160 mL/min |

42 |

N/A |

Photo |

Auto CAD

&

3D |

155 |

| UAG-30K-W |

30kHz

Wide Spray Ultrasonic Atomizer |

0 - 160 mL/min |

32 |

Data |

Photo |

Auto CAD

&

3D |

134 |

| UAG-40K-W |

40kHz

Wide Spray Ultrasonic Atomizer |

0 - 50 mL/min |

26 |

Data |

Photo |

Auto CAD

&

3D |

100 |

| UAG-60K-W |

60kHz

Wide Spray Ultrasonic Atomizer |

0 - 40 mL/min |

20 |

Data |

Photo |

Auto CAD

&

3D |

91 |

| UAG-120K-W |

120kHz

Wide Spray Ultrasonic Atomizer |

0 - 20 mL/min |

12.5 |

Data |

N/A |

Auto CAD

&

3D |

94 |

| UAG-130K-W |

130kHz

Wide Spray Ultrasonic Atomizer |

0 - 20 mL/min |

11.8 |

Data |

N/A |

Auto CAD

&

3D |

92 |

|

|

|

| |

|

Narrow Spray Ultrasonic Atomizers come with both ultrasonic generator and nozzle included. Purchase of

parts separately is available as well.

|

Description:

- The narrow spray ultrasonic atomizer nozzles have the narrowest spray pattern due to the flat tip design. This atomizer nozzle is very popular for extra low flows in the ul/min range. Drop diameter provided is with the Lang formula below. For actual measured particle data using a DCIII particle counter see DATA link next to each nozzle.

- The tube connection at the rear is for a 1/8" diameter Swage-lock, allowing connection of various fittings and manifolds for introduction of multiple liquids and gases.

| |

Model |

Item

description |

Flow Rate |

Drop Diameter (microns) |

Particle Distribution Data |

Photo |

Drawings |

Weight

(grams) |

| UAG-40K-N |

40kHz

Narrow Spray Ultrasonic Atomizer |

0 - 40 mL/min |

26 |

Data |

Photo |

Auto CAD

&

3D |

100 |

| UAG-60K-N |

60kHz

Narrow Spray Ultrasonic Atomizer |

0 - 40 mL/min |

20 |

Data |

Photo |

Auto CAD

&

3D |

91 |

| UAG-120K-N |

120kHz

Narrow Spray Ultrasonic Atomizer |

0 - 20 mL/min |

12.5 |

Data |

Photo |

Auto CAD

&

3D |

94 |

| UAG-130K-N |

130kHz

Narrow Spray Ultrasonic Atomizer |

0 - 20 mL/min |

11.8 |

Data |

Photo |

Auto CAD

&

3D |

92 |

|

|

|

| |

|

The Radial Flow Ultrasonic Atomizer comes with both ultrasonic generator and nozzle included. Purchase of

parts separately is available as well.

|

Description:

- The Radial Flow Ultrasonic Atomizer Nozzle sprays liquid through four small holes drilled into the side of the vibrating tip. This nozzle is good for coating vials and counter bores. Drop diameter provided is with the Lang formula below. For actual measured particle data using a DCIII particle counter see DATA link next to the nozzle.

- The tube connection at the rear is for a 1/8" diameter Swage-lock, allowing connection of various fittings and manifolds for introduction of multiple liquids and gases.

|

|

Model |

Item

description |

Flow Rate |

Drop Diameter (microns) |

Particle Distribution Data |

Photo |

Drawings |

Weight

(grams) |

| UAG-40K-NR |

40kHz

Radial Flow Ultrasonic Atomizer |

0 - 10 mL/min |

26 |

Data |

Photo |

Auto CAD

&

3D |

135 |

|

|

|

| |

|

High Operating Temperature Ultrasonic Atomizers come with both ultrasonic generator and nozzle included. Purchase of

parts separately is available as well.

|

Description:

- The high temperature atomizer nozzle can be used in an environment where the tip temperature can reach as high as 1000 degrees F. Along the tip extension is a thread for attaching to a chamber being heated. This atomizer is good for fuels being burned and high temperature spray drying.

- The tube connection at the rear is for a 1/8" diameter Swage-lock, allowing connection of various fittings and manifolds for introduction of multiple liquids and gases.

|

Model |

Item

description |

Flow Rate |

Drop Diameter (microns) |

Particle Distribution Data |

Photo |

Drawings |

Weight

(grams) |

| UAG-30K-WT |

30kHz

High Temperature Wide Spray Ultrasonic Atomizer |

0 - 100 mL/min |

32 |

N/A |

N/A |

Auto CAD

&

3D |

N/A |

| UAG-40K-NT |

40kHz

High Temperature Narrow Spray Ultrasonic Atomizer |

0 - 50 mL/min |

26 |

N/A |

N/A |

Auto CAD

&

3D |

N/A |

Atomizer Digital Ultrasonic Generator

The digital ultrasonic generator for atomizers with five icon front panel. Programable with LCD display, variable power control, probe selection, run time, contrast adjustment, external enable/disable. Menu driven software for selecting operating frequency from 20kHz to 130kHz. Operates from 110/220VAC, 50/60Hz. Fifty Watts maximum output, can operate any ultrasonic transducer. Windows PC Controler externally operates all functions of the generator, purchased separately.

- Small size 9 1/4" x 8" x 3 3/4". Weight 2.3 lbs (1045 grams)

- Order with 110VAC US, 220/240VAC Euro or UK Plug

- Will operate one of eight ultrasonic atomizer nozzles selected from menu. Generator is included with all atomizer probes.

|

|

|

|

|